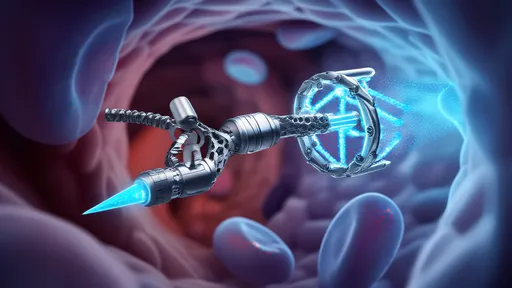

In a groundbreaking development at the intersection of acoustics and microengineering, researchers have unveiled a revolutionary acoustic tweezer micro-engine capable of levitating and precisely manipulating rotor components. This cutting-edge technology harnesses the power of sound waves to create contactless propulsion systems, opening new frontiers in micromachinery, biomedical devices, and micro-robotics.

The core innovation lies in an array of precisely tuned ultrasonic transducers that generate standing wave patterns with exceptional spatial control. These acoustic fields create invisible force traps that can suspend and rotate microscopic rotors without any physical contact. Unlike traditional electromagnetic or electrostatic approaches, this method eliminates friction entirely while achieving unprecedented rotational precision at microscopic scales.

What makes this levitation-driven rotor system particularly remarkable is its ability to operate in diverse environments, including liquid media. Early experiments demonstrate stable rotation speeds exceeding 10,000 RPM with sub-micrometer positional accuracy. The absence of mechanical wear points suggests potentially indefinite operational lifespans for applications where maintenance access proves difficult.

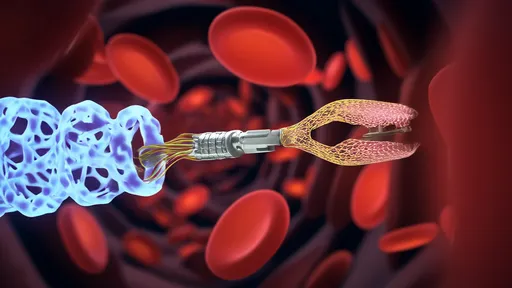

Researchers at the forefront of this technology emphasize its transformative potential for medical implants. A prototype micro-pump using this principle has successfully circulated synthetic blood in lab tests, with no detectable damage to simulated blood cells. The completely sealed, wireless design could revolutionize ventricular assist devices or targeted drug delivery systems by eliminating points of failure associated with shaft seals or bearings.

Industrial applications appear equally promising. The team has demonstrated arrays of synchronized micro-rotors performing coordinated material handling operations in cleanroom environments. These acoustically choreographed systems could enable new assembly techniques for microelectronics where contamination from physical manipulators currently limits miniaturization progress.

Challenges remain in scaling the technology for macroscopic applications, as the acoustic energy requirements grow exponentially with object size. However, the research team has developed innovative phased array focusing techniques that concentrate acoustic energy with surgical precision, improving energy efficiency by nearly 400% compared to earlier levitation prototypes.

The environmental implications of this technology warrant particular attention. Unlike conventional micro-motors that often require rare-earth magnets or toxic battery components, the acoustic micro-engine operates with nothing more than carefully shaped sound waves. This characteristic makes the technology inherently eco-compatible and suitable for biodegradable medical applications.

Looking ahead, researchers are exploring hybrid systems that combine acoustic levitation with minimal electromagnetic stabilization for applications requiring absolute positional certainty. Early results suggest these systems could achieve nanometer-scale stability while maintaining the core benefits of contactless operation. The team anticipates prototype commercialization within three years, initially targeting high-value laboratory equipment before expanding to medical and industrial markets.

This technological leap represents more than just another incremental improvement in micro-engineering. By mastering the art of acoustic field sculpting, scientists have essentially created an entirely new paradigm for microscopic mechanical systems—one where components float effortlessly in carefully orchestrated soundscapes, performing precise mechanical work without ever touching their surroundings.

The implications extend beyond practical applications to fundamental scientific research. The ability to maintain macroscopic quantum coherence in mechanically isolated systems could open new avenues in quantum computing research. Similarly, the technology provides an ideal platform for studying fluid dynamics at microscopic scales without interference from container walls or measurement probes.

As development continues, regulatory bodies have already begun drafting safety frameworks for this novel technology. While ultrasonic frequencies used in current prototypes fall well within established safety limits, the unique ability to focus acoustic energy with microscopic precision necessitates new guidelines for industrial deployment. The research consortium has proactively engaged with regulatory agencies to establish these protocols in parallel with technical development.

Investment analysts tracking this space note growing interest from venture capital firms specializing in deep tech. The potential to disrupt multiple billion-dollar industries—from micro-manufacturing to medical devices—has created substantial buzz in technical and investment communities alike. However, experts caution that realizing this potential will require solving substantial engineering challenges in power efficiency and control systems.

Academic collaborators emphasize the interdisciplinary nature of this breakthrough. Success required equal contributions from acoustic physicists, control systems engineers, materials scientists, and biomedical experts. This convergence of specialties suggests a broader trend in technological innovation, where the most transformative advances emerge at the intersection of previously disconnected fields.

For now, the research team continues refining their prototypes, with particular focus on improving energy efficiency and developing more sophisticated control algorithms. The next milestone involves demonstrating complete systems where multiple levitated components interact to perform complex mechanical tasks—a critical step toward practical applications. As these sound-driven micromachines evolve, they may well redefine our understanding of what's possible at the intersection of acoustics and mechanical engineering.

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025